Let automatics work for you By John S. Ball III

It is important to understand automatics and use them as much as possible so these factors can be controlled by the machine and not left up to the possibility of human error. Although this does not cover every little nook and cranny, here are a few tips to help achieve mat quality.

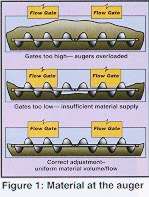

It is important to understand automatics and use them as much as possible so these factors can be controlled by the machine and not left up to the possibility of human error. Although this does not cover every little nook and cranny, here are a few tips to help achieve mat quality. nice and full. Veteran team members also know the flow gates have to be adjusted properly so when the mix is drawn back by the conveyors, we end up with an even texture of materials coming back and dropping off into the auger chamber. That's how we get the right head of material, assuming the paver is running at a continuous, consistent speed.

nice and full. Veteran team members also know the flow gates have to be adjusted properly so when the mix is drawn back by the conveyors, we end up with an even texture of materials coming back and dropping off into the auger chamber. That's how we get the right head of material, assuming the paver is running at a continuous, consistent speed. We want to get the material to the back of the screed evenly and without segregation, and we want to move it as a mass.

We want to get the material to the back of the screed evenly and without segregation, and we want to move it as a mass. We must stop bypassing the sensors because they affect the pressure on the screed. As we interrupt the flow of material, mat texture is affected. We wind up with too much material, the screed tries to ride over it, and we have a harder time achieving uniform pressure across the screed.

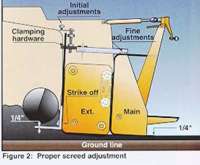

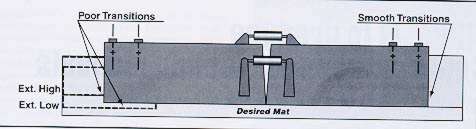

We must stop bypassing the sensors because they affect the pressure on the screed. As we interrupt the flow of material, mat texture is affected. We wind up with too much material, the screed tries to ride over it, and we have a harder time achieving uniform pressure across the screed. You also want to run a straightedge from front to back of the screed to check misalignment of the extension, the pre-strikeoff if your paver has one, and the permanent pre-strikeoff. You are making sure all the screed parts are adjusted properly (see above).

You also want to run a straightedge from front to back of the screed to check misalignment of the extension, the pre-strikeoff if your paver has one, and the permanent pre-strikeoff. You are making sure all the screed parts are adjusted properly (see above).Home | Articles | Qualification | Calculators

Top Quality Paving

PO Box 4398

Manchester, New Hampshire 03108

Cell Phone 603-493-1458

Write to us at our E-mail address for more information

Visit Asphalt Contractor Magazine Online!

WebMaster: Sullivan+Wolf Design, LLC